Contact Supplier

Ms. Bella

Leave a message| Unit Price: | USD 55000 - 60000 / Set/Sets |

|---|---|

| Payment Type: | T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

Basic Info

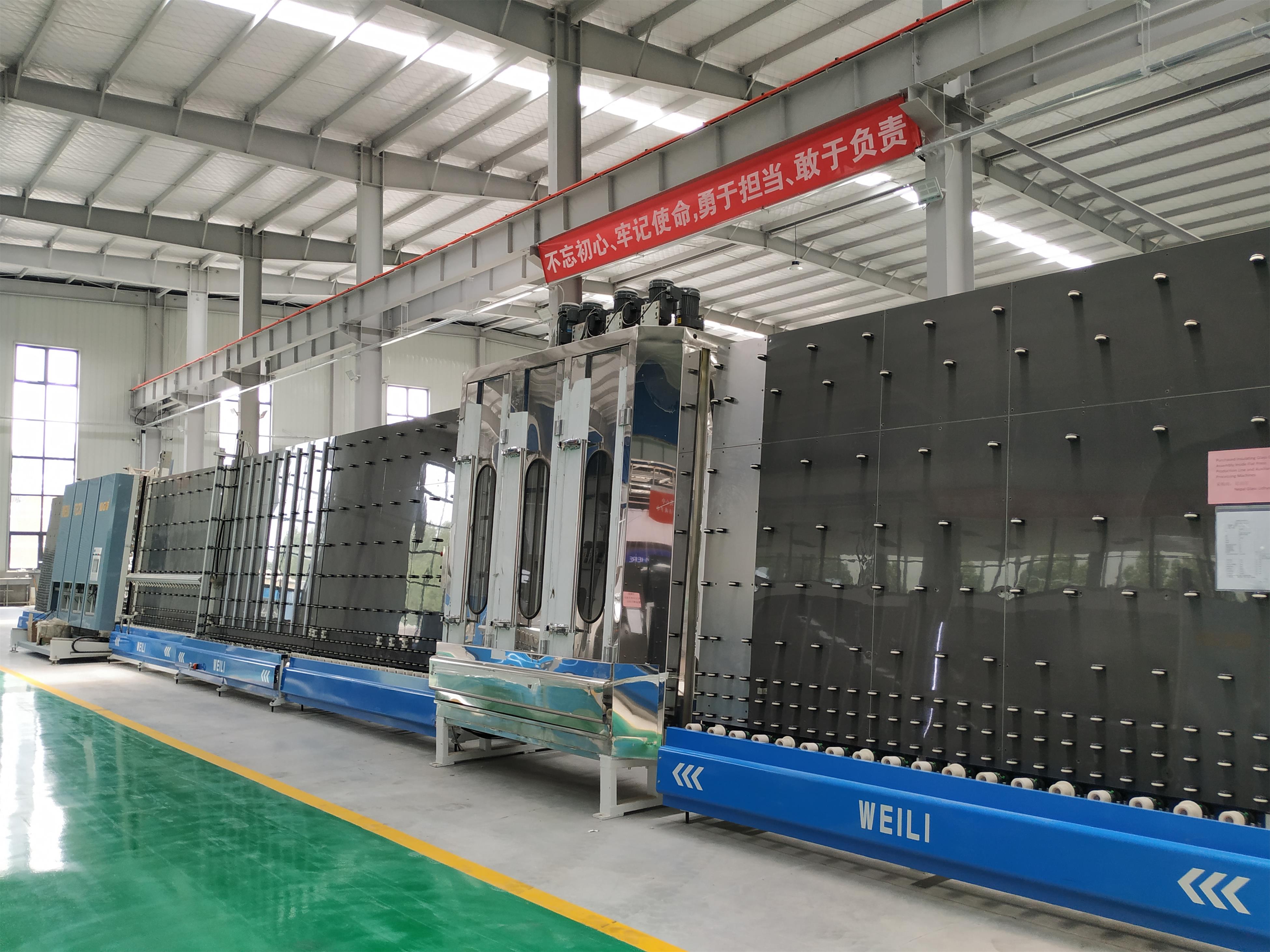

Model No.: LBW2500PC

Brand: WGM

Applicable Industry: Manufacturing Plant, Construction Works

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Turkey, Germany, Viet Nam, India, South Korea

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Turkey, Germany, Viet Nam, India, South Korea

Old And New: New

Machine Type: Insulating Glass Production Line

Place Of Origin: China

Certification: Ce, UL

Warranty Period: 1 Year

Core Selling Point: High Safety Level

Glass Thickness: 3-19mm

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: Hot Product 2019

Core Component Warranty Period: 1 Year

Core Components: Motor, Plc, Engine

Type: Insulating Glass Production Line

Structure: Vertical

Control System: PLC

Condition: New

Flow Volume: 0.8m3/min

Compressed Air: 800L/min

Min.glass Size: 300x400mm

Max.glass Size: 2500x3000mm

Air Pressure: 1Mpa

Additional Info

Packaging: plywood pallet and plastic film

Productivity: 650-700units / 8hours

Transportation: Ocean,Land

Place of Origin: Shandong, China

Supply Ability: 100 sets/year

Certificate: ISO-9001/CE/SGS/UL/CSA

HS Code: 84649019

Port: Qingdao Port

Payment Type: T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

2.5m Automatic Insulating Glass Argon Gas Filling Production Line is controlled by Schneider PLC system to ensure stable and reliable equipment operation. The washing section adopt 3 patr of soft brushes for washing LOW-E glass. The washing machine of Automatic Insulating Glass Gas Filling Line adopt high-pressure fan to ensure fast cleaning speed. Double Glazing Argon Gas Filling Machine flat press can inflate the insulating glass online, with an inflation concentration of more than 85%. The best inflation space can be automatically adjusted according to the glass size, saving gas consumption. Insulating Glass Gas Filling Processing Line argon gas concentrate can meet CE requirement and get great feedback from customers.

Insulating Glass Machine Feature:

Hot sale Automatic Insulating Glass Machine and Double Glazing Machine with blue and black color

1* The entire machine’s operation uses the man-machine contact surface.

2* High production efficiency: The big glass can move at the full speed, the small glass is possible to stop in storage area, and stay at the storage area temporarily, also the clean glass may input continuously.

3* Conserves energy interrupted type automatic operation system

Technical parameter

| Power Supply | 380V/50HZ 37.5Kw |

| Dimension(LxWxH) | 21600x2600x3450mm |

| Production quantity | 700-800IG units/8hs |

| Max Glass Size | 2500x3000mm |

| Min Glass Size | 350x400mm |

| Washing Glass Thickness | 3-15mm |

| Washing Glass Speed | 0-10m/min |

| Insulating Glass Thickness | ≤48mm |

| Transmission Glass Speed | 0-45m/min |

| Compressed Air: | 800L/min |

| Air Pressure: | 0.7Mpa |

| Environment Temperaturer | 7~50℃ |

| Brush | 6 pieces, include 3 LOW-E brushes |

More details:

Washing and Drying sector(★Using 304 stainless steel, the pre washing section is optional★)

Outside assembly section(★ Working more efficiency★)

Inside Argon Gas Filling Flat Press section(★ the asgon gas concentrate is always higher than 85%★)

After-sales service:

* Provide factory layout according to your factory size in advance

* Provide English Version of Installation/Operation/Service/Maintenance Manual.

* Engineers available to service machinery overseas.

* Online support

* Video technical support

* Field maintenance and repair service

* Field installation commissioning and training

Product Categories : Insulating Glass Production Line > Automatic Insulating Glass Gas Filling Production Line

Hot Products