Contact Supplier

Ms. Bella

Leave a message| Unit Price: | USD 4500 - 8000 / Set/Sets |

|---|---|

| Payment Type: | L/C,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Min. Order: | 1 Set/Sets |

Basic Info

Model No.: WL2000

Brand: Weili

Type: Insulating Glass Production Line

Certification: PDA

Structure: Vertical

Control System: PLC

Glass Washing Machine Type: Ultrasonic Glass Washing Machine

Condition: New

Additional Info

Packaging: Film and pallet

Productivity: 500 sets

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 40 sets per month

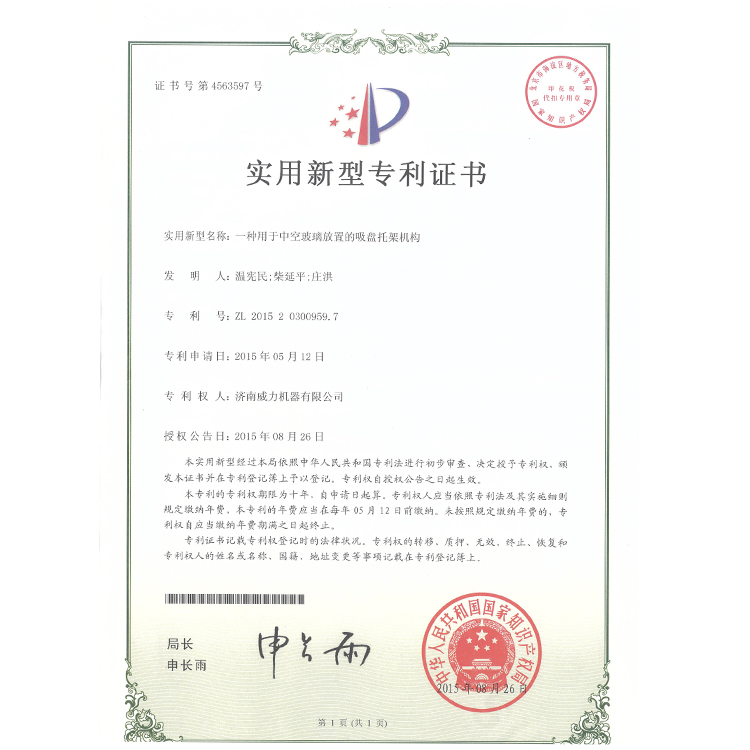

Certificate: CE/ISO/UL/UR

HS Code: 84649019

Port: Qingdao Sea Port

Payment Type: L/C,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA

Features for fully automatic Insulating glass butyl extruder

1. This butyl extruder is full automatic.

2. the whole body frame is made by CNC bended stainless steal

3. applied 5.7 inches color man-machine interface, at the same time, PLC Control system can be oriented and

transfer

4. adopt stepless speed regulation and ensure aluminum frame transmission stable

5. Auto-induction system induct aluminum width and adjust the distance between nozzles, which can make extrude evenly

6. adjust import MAXIMATOR Pneumatic and hydraulic supercharging system and make supply voltage stable,

guarantee extrude evenly.

7. butyl cylinder can contain 14L butyl and it is so convenient and save time

Technique parameter:

| Machine size | 3000mm(L)x600mm(W)x950mm(H) |

| Spacer width | 6mm-25mm |

| Minimal size | 250mmx250mm |

| Maximal size | 2500mmx2500mm |

| Speed | 0-25m/min |

| Butyl volume | 14L |

| Power supply | AC380V 3ph 50HZ |

| Total power | 3.75kw |

Main components

| NO. | Name | Brand |

| 1 | PLC | SCHNEIDER |

| 2 | 10.0 inch touch screen | SCHNEIDER |

| 3 | Photoelectric switch | AUTONICS |

| 4 | Limit switch | AUTONICS |

| 5 | Transducer | SCHNEIDER |

| 6 | Low voltage electric components | SCHNEIDER |

| 7 | Solenoid valve | AIRTAC |

| 8 | Cylinder | AIRTAC |

| 9 | Liner guide rail | PMI |

| 1 | Bearing of cleaning section | SKF |

| 11 | Servo motor | SIMENS / SCHNEIDER |

| 12 | Transmission motor | DPG |

Our related products:

CNC Vertical Glass Drilling and Milling Machine

Vertical Auto Gas Filling Production Line

Product Categories : Hot Melt Butyl Extruder Machine > Automatic Butyl Extruder Machine

Hot Products